Best Excel Tutorial

The Largest Excel Knowledge Base ✅ The Best Place to Learn Excel Online ❤️

Design of Experiments (DOE) in Excel

Design of Experiments (DOE) is a valuable methodology for optimizing processes and products through systematic experimentation. While conducting complex DOE analyses may require specialized software, Excel can be a useful tool for basic DOE tasks and preliminary analysis.

Here’s a guide on how to use Excel for Design of Experiments:

Table of Contents

Define Your Experiment

Clearly define the purpose and goals of your experiment. Determine the factors (variables) you want to study, the levels of those factors, and the response variable you’re trying to optimize or understand.

Create an Experimental Design

Excel doesn’t have built-in tools for generating full experimental designs, but you can create basic designs manually. Use Excel’s worksheet to organize your experiment by listing factors, levels, and experimental runs.

Conduct Experiments

Perform the experiments according to your defined design. Record the data in Excel, with each row representing an experimental run and each column corresponding to a factor or the response variable.

Perform Preliminary Analysis

Excel provides various statistical functions that can help you analyze your experimental data. You can calculate means, standard deviations, and other descriptive statistics to gain insights into your data’s behavior.

Create Visualizations

Use Excel’s charting capabilities to create visual representations of your data. Visualizations like scatter plots, histograms, and line charts can help you identify trends and patterns.

Regression Analysis

Excel’s regression analysis tools can be helpful in determining the relationship between your factors and the response variable. You can perform simple linear regression or multiple regression to model these relationships.

Optimize Your Process

If your goal is optimization, you can use Excel’s Solver add-in to find the optimal settings for your factors that maximize or minimize the response variable. Define your objective function and constraints within Solver to perform optimization.

Interpret the Results

Carefully interpret the results of your experiments and analyses. Determine which factors have the most significant impact on the response variable and make informed decisions based on your findings.

Related posts:

Search This Blog

Polyhedrika.

Lean Six Sigma Process Improvement

Response Surface Design Of Experiments with Excel

Factorial Experiments

We now use Excel Data Analysis/ Regression:

Response Surface Designs

Run Response Surface CCI Experiments

To Run These Experiments with our Simulator

Analysis with Solver

- Solver

- Regression.

- An intercept coefficient (1)

- Factors each with a coefficient (3)

- 2 way interactions with their coefficients (3)

- Squares of each factor with their coefficients (3)

Process Optimization with Solver

Analysis with Regression

Optimize Process Yield with Solver

- We add cells R16 to R24 to house the values calculated by Solver.

- Solver only needs to calculate pH (R18) and Time (R19).

- R21 to R23 are calculated with a formula from these two values.

- R17 = 1 to multiply with the intercept coefficient in N17.

- The formula for Yield in R24 is =SUMPRODUCT(N17:N23;R17:R23) .

- The result from Solver is:

Response Surface Graph

Residuals Analysis

Residuals Normality

Test for Trends in the Residuals

Confirmation Runs

Conclusions

- Design of Experiments can be used to approximate linear or quadratic models to our process response in order to understand its behavior.

- It allows the identification of critical factors affecting the response.

- With a regression analysis, we obtain a mathematical formula, to estimate the process response as a function of these factors.

- We can then find the values of these factors that optimize the response.

- Very often we find a close to linear relationship between factors and response in our area of interest, then we can use a linear regression DOE

- If these relationships are not linear we can use Response Surface DOE as we have just seen.

- All this analysis can be performed with Excel Statistical Analysis tools, Solver, Pivot Charts, etc.

- Another example of non linear DOE: The Catapult exercise

Post a Comment

Popular posts from this blog, design of experiments (doe) with excel.

Virtual Obeya Room

Let's Excel Analytics Solutions LLP

Analytics. Intelligence. Excellence

- Free DoE Excel Worksheet

Full factorial Design of Experiments (DOE) is a method used to study the effects of multiple factors on a response variable. In this type of experiment, all possible combinations of the levels of the factors are tested. This allows for the determination of the main effects and interactions of the factors on the response variable. Full factorial DOE is useful when there are a small number of factors, and their levels are fixed. It is a powerful tool for understanding complex systems, but it can be impractical when there are a large number of factors or when the number of runs required becomes infeasible.

Submit this form to download the Full Factorial DoE Solved Excel Worksheet to learn how to calculate main effects, interaction effects, and ANOVA Table for your full factor DoE.

- Data Analytics Solutions

- ERP Solutions

- CRM Solutions

- I agree to allow letsexcel.in to store and process my personal data to receive other communications from letsexcel.in.

- Training and Consulting Services

- Free Chemometrics Software

- Demo Request

- Free Trial Request Form

- Free Webinars

- Free Data Analytics Case Studies

- Data-sets for Machine Learning Practice

- 800 -274-2874

- [email protected]

Experimental Design

Home » SPC for Excel Software » Experimental Design

Experimental design techniques are designed to discover what factors or interactions have a significant impact on a response variable. Our SPC for Excel provides an easy-to-use design of experiments (DOE) methodology in the Excel environment you know. The SPC for Excel software contains the following DOE routines:

- Two-Level Full Factorial Designs (up to 7 factors)

- Fractional Factorial Designs (29 different designs, two-level, up to 15 factors

- Plackett-Burman Designs (up to 27 factors)

Watch a Video Highlighting SPC for Excel's Experimental Design Capabilities!

Join those in over 80 countries using spc for excel, experimental design features.

- Full factorials

- Fractional factorials

- Plackett- Burman

- Design table analysis

- ANOVA Table for factors and interactions

- ANOVA for model

- Model for coded and actual factors

- Design statistics

- Standard deviation

- Coefficient of variation

- Adjusted R square

- R square prediction

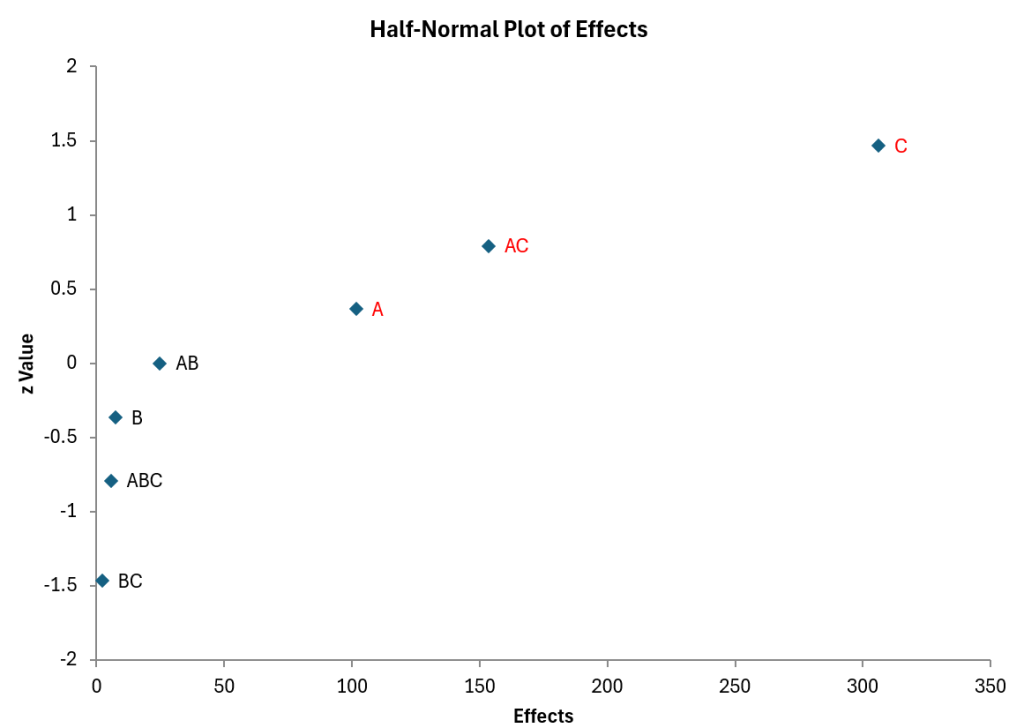

- Normal plot of effects

- Half-normal plot of effects

- Effects charts

- Two factor charts

- Residuals analysis

- Standardized residuals

- Internally studentized residuals

- Externally studentized residuals

- Cook's distance

- Potential outliers in red

- Residuals charts (raw, standardized, internally or externally studentized residuals)

- Normal plot

- Versus predicted values

- Versus actual run number

- Other charts

- Predicted vs actual

- DFFITS, Cook's distance and leverage versus actual run number

- DOE optimization chart

- Easily select effects to include/exclude in the analysis

SPC Knowledgebase Newsletter and Videos

Lean Six Sigma & SPC Excel Add-in

- Questions? Contact Us

- 888-468-1537

Key Tools in QI Macros

Control charts, pareto charts, fishbone diagrams, gage r&r studies.

- Data Mining Tools

Statistical Tools

Smart wizards.

Knowledge Base - All Tools

- Free 30-Day Trial

- Powerful SPC Software for Excel

- SPC - Smart Performance Charts

- Who Uses QI Macros?

- What Do Our Customers Say?

- QI Macros SPC Software Reviews

- SPC Software Comparison

- Control Chart

- Histogram with Cp Cpk

- Pareto Chart

- Automated Fishbone Diagram

- Gage R&R MSA

- Statistical Analysis - Hypothesis Testing

- Chart and Stat Wizards

- Lean Six Sigma Excel Templates

- Technical Support - PC

- Technical Support - Mac

- QI Macros FAQs

- Upgrade History

- Submit Enhancement Request

- Data Analysis Services

- Free QI Macros Webinar

- Free QI Macros Video Tutorials

- How to Setup Excel for QI Macros

- Free Healthcare Data Analytics Course

- Free Lean Six Sigma Webinars

- Animated Lean Six Sigma Video Tutorials

- Free Agile Lean Six Sigma Trainer Training

- Free White Belt Training

- Free Yellow Belt Training

- Free Green Belt Training

- QI Macros Resources

- QI Macros Knowledge Base | User Guide

- Excel Tips and Tricks

- Lean Six Sigma Resources

- QI Macros Monthly Newsletter

- Improvement Insights Blog

- Buy QI Macros

- Quantity Discounts and W9

- Hassle Free Guarantee

Lean Six Sigma Templates in QI Macros

Improvement tools, doe, gage rr, fmea, calculators & formulas, planning & pm tools.

Lean Six Sigma Quick Reference Card

QI Macros Reviews CNET Five Star Review Industry Leaders Our Customers

Home » Lean Six Sigma Templates » Design of Experiments

Struggling with Design of Experiments (DOE)?

Qi macros doe templates for excel can help, ...even if you don't know anything about doe.

QI Macros DOE Template

- Click on QI Macros menu > DOE Gage R&R > DOE.

- Conduct tests and enter your data in the template.

- QI Macros does the rest.

What is Design of Experiments?

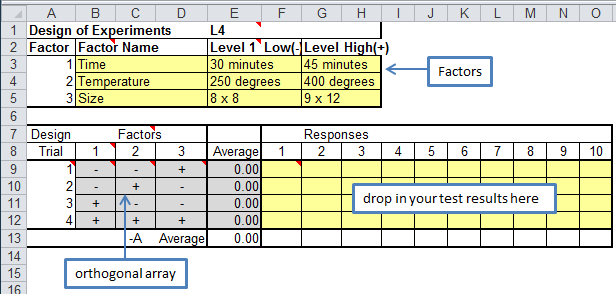

Design of Experiments (DOE) is a systematic way to determine the best combination of factors in a process to optimize results. A simple example is the ideal combination of time, temperature and pan size when baking a cake. Without DOE , you're stuck with the world's slowest method for success-trial and error.

Design of Experiments , enables you to limit tests to the high (+) and low (-) values for any particular "design factor" (e.g., time, temperature, size, etc.), NOT every increment in between. AND you can test more than one factor at a time.

Required tests are identified and tracked through "orthogonal arrays" and alot of behind the scenes calculations. Fortunately, DOE software like QI Macros DOE templates in Excel can do the heavy lifting for you. All you need to do is run the designated tests and drop in your data.

Example of an Orthogonal Array

An orthogonal array is simply the list of the tests you need to run to perform a design of experiments. Below is an example of QI Macros L4 Taguchi template where we are testing three factors. The orthogonal array lists 4 different combinations (trials) to test.

For example, trial 1 is: cell B9 "-" Lowest time (30 min) with cell C9 "-" Lowest temp (250 degrees) with cell D9 "+" Highest pan (9x12). You would conduct this test up to 10 times and record the results in cells F9 to O9. In our cake example, the results would be subjective (rating from 1 to 10 by tasters.) In most manufacturing tests the results would be objectively measured.

What is Confounding?

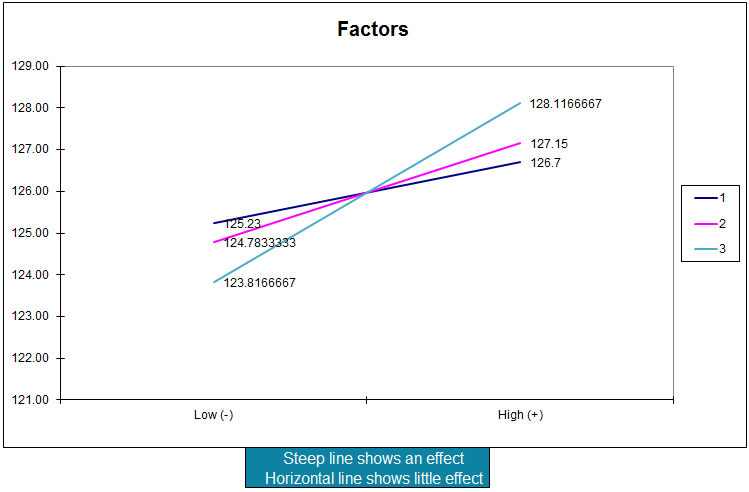

A common DOE term is "confounding," which simply means that one factor affects another. You'd expect a higher temperature to result in a shorter cooking time, and vice versa, but does a square pan take longer than a round one? Using the results of your tests, doe software will draw the interactions between each of the factors as a line graph.

If the two lines are parallel, there's no interaction. Is one end higher than the other? If so, you can immediately tell which value (high/low) gives you the best result.

If the two lines cross, there is an interaction (confounding). And, by looking at where the two lines intersect on the graph, you can determine the optimum settings (e.g., time and temperature to get the best cake).

Examples of charts created by QI Macros DOE Templates

Benefits of Using Design of Experiments

Design of Experiments can help you shorten the time and effort required to discover the optimal conditions to produce Six Sigma quality in your delivered product or service. Don't let the +/- arrays baffle you. Just pick 2, 3, or 4 factors , pick sensible high/low values, and design a set of experiments to determine which factors and settings give the best results.

Start with a 2-factor and work your way up. It's just not that hard, especially with the right software.

You don't have to be an expert. Use QI Macros DOE Template to mistake-proof your calculations.

Download a free 30-day trial. get the doe template now, other tools included in qi macros add-in for excel.

- SPC Software for Excel

- Free 30 Day Trial

- On-line Tech Support

- QI Macros Reviews

- Free QI Macros Training

- Privacy Policy

KnowWare International, Inc. 2696 S. Colorado Blvd., Ste. 555 Denver, CO 80222 USA Toll-Free: 1-888-468-1537 Local: (303) 756-9144

Most Practical DOE Explained: Tips and Tricks to Design Your Experiments

Published: October 14, 2024 by Kim Niles

© Oakland Images/Shutterstock.com

- An eight-run array is the most practical means of constructing a DOE.

- You can do this with Microsoft Excel, but dedicated math software is better suited for the task.

- There are multiple forms of DOE, each with an intended use.

For purposes of learning, using, or teaching a design of experiments (DOE), one can argue that an eight-run array is the most practical and universally applicable array that can be chosen. There are several forms of and names given to the various types of these eight-run arrays (e.g., 2^3 Full Factorial, Taguchi L8, 2^4-1 Half Fraction, Plackett-Burman 8-run, etc.), but they are all very similar.

Generic Steps for Creating a Practical DOE

©Ground Picture/Shutterstock.com

Determine the acceptance criteria you need (i.e., acceptable alpha error or confidence level for determining what you will accept as passing criteria). This is typically alpha=.05 or 95 percent confidence for solid decisions; see additional advice below.

- Pick 2-3 factors to be tested and assign them to columns A, B, and C as applicable (use the key provided).

- Pick 2 different test levels for each of the factors you picked (i.e., low/high, on/off, etc.).

- Determine the number of samples per run(room for 1-8 only; affects normality and affects accuracy, not confidence).

- Randomize the order to the extent possible.

- Run the experiment and collect data. Keep track of everything you think could be important (i.e., people, material lot numbers, etc.). Keep all other possible control factors as constant as possible as these may affect the validity of the conclusions.

- Analyze the data by entering the data into the yellow boxes of the spreadsheet and reading the results. A review of the ANOVA table will show you those effects that meet the acceptance criteria established in step number one. If the alpha value in the table is greater than the acceptance criteria, accept the result; if it is less, reject the result. Similarly, the higher the confidence, the higher the probability that that factor is statistically different from the others. Signal-to-noise measurements are helpful to use when selecting factors for re-testing in subsequent experiments.

- Confirm your results by performing a separate test, another DOE, or in some other way before fully accepting any results. You may want to more closely define results that are close to your acceptance criteria by retesting the factor using larger differences between the levels.

How Does a DOE Work?

Note that using the eight-run array, we have four runs being tested with each factor at high levels and four without being at a high level. We have the equivalent of eight data points comparing the effects of each high level (4 high + 4 not high = 8 relative to high) and vice versa for each factor and the interactions between the three factors.

Therefore, using this balanced multifactor DOE array, our eight-run test becomes the statistical equivalent of a 96-run, one-factor-at-a-time (OFAT) test [(8 Ahigh)+(8 Alow)+(8 Bhigh)+(8 Blow)+(8 Chigh)+(8 Clow)+(8 ABhigh)+(8 ABlow)+(8 AChigh)+(8 AClow)+(8 BChigh)+(8 BClow)].

Other advantages to using DOE include the ability to use statistical software to make predictions about any combination of the factors in between and slightly beyond the different levels, and generating various types of informative two- and three-dimensional plots. Therefore, DOEs produce orders of magnitude more information than OFAT tests at the same or lower test costs.

DOEs don’t directly compare results against a control or standard. They evaluate all effects and interactions and determine if there are statistically significant differences among them. They also calculate statistical confidence levels for each measurement.

A large effect might result but if the statistical confidence for that measurement is low then that effect is not believed. On the other hand, a small measured effect with high confidence tells us that the effect isn’t important.

Why Use This Resource?

You might be asking why you’d need a practical DOE guide. However, you could spend the time generating personal resources and trying to instruct your team on their usage. Save a little time and effort and just trust the process. This is vetted by industry veterans and introduces new users to the concepts behind DOEs with ease.

Why This Array?

Selecting a test array requires balancing your test objectives, test conditions, test strategy, and resources available. Therefore, it is usually more advantageous to run several DOEs testing only a few factors at once than one large DOE.

Comparing the statistical power of this array (inherent ability to resolve differences between test factors; 1-b) with the cost of experimenting (number of runs needed) also shows how this array is advantageous since it requires only eight runs and yields successful results in most situations.

Picking Acceptance Criteria

Acceptable confidence depends upon your needs. If health could be affected, then you may want more than 99 percent confidence before making a decision. This author’s rule of thumb is that 51-80 percent is considered low but in some cases is worth considering (see precautions below).

A confidence level of 80-90 percent is considered moderate with the results likely to be at least partially correct and a confidence level greater than 90 percent is considered high with the results usually considered very likely to be correct.

Calculating Samples Per Run

Since statistical confidence doesn’t increase with additional samples per run (replications are needed to have that effect), it is important to remember that additional samples per run are only needed when concerns of non-normal data exist (per the central limit theorem) and or to improve measured effect accuracy (significance of changes between test levels).

Since test costs and/or knowing the statistical confidence in our effects is usually more important than statistical significance and normality effects, running two to three samples per run is usually ideal.

Other Useful Tools and Concepts

Do you want to learn more about DOEs? You’ve come to the right place. Learning how Plackett-Burman Experimental Design factors into your DOE can be a lifesaver. This method screens out the chaff and lets you hone in on the most important factors to focus on in your experiments.

Additionally, learning how full factorial design works can show the impact of variables on your outputs. This isn’t for beginners but is something that certainly merits attention for anyone conducting their DOEs.

Precautions

Since this array has less power than others available, we need to remember that when optimizing a process that isn’t critical to human safety, using test results with a low confidence level can often be much better than not knowing which way to go with machine settings, etc.

Assuming all the errors in one’s experiment are evenly distributed (random distribution of error), a confidence level of 60 percent (measured to be true via DOE), for example, might seem horrible but means the equivalent of 80 percent, since the 40 percent that we are unsure of could go either way [60 percent + (40 percent / 2) = 80 percent].

The image featured at the top of this post is ©Oakland Images/Shutterstock.com.

Join 65,000 Black Belts and Register For The Industry Leading ISIXSIGMA Newsletter Today

About the author.

IMAGES

VIDEO

COMMENTS

Tutorial on Design of Experiments (RCBD, Split-Plot, Latin Squares, 2^k Factorial) and how to analyze these designs in Excel. Examples & software are included.

We will use an example in this Excel file you can download: Download file ExcelResponseSurface.xlsm from OneDrive to your PC. In this example we are trying to maximize process yield acting on the critical factors pH , Temperature and Time . We will run the experiments in the Experiments simulation sheet using coded values.

Use Excel's worksheet to organize your experiment by listing factors, levels, and experimental runs. Conduct Experiments. Perform the experiments according to your defined design. Record the data in Excel, with each row representing an experimental run and each column corresponding to a factor or the response variable. Perform Preliminary ...

This DOE example uses a familiar task and simple DOE template in Excel. You don't have to be an expert. Lean Six Sigma & SPC Excel Add-in. QI Macros 30-Day Trial . ... You can also use the "Create Input Table" to create an Input sheet summarizing the responses for Regression Analysis. ... Performing a Design of Experiments ...

Download a free Excel template for design of experiments (DOE) from ASQ to help you set up and analyze your experiments effectively.

Design of Experiments is a useful methodology for process improvement. The purpose is to find a relationship between process variables we can control and key process outputs in order to increase process capability. You can use Excel statistical analysis tools, Solver, Pivot charts, etc. to plan and analyse the results of these experiments.

Free DoE Excel Worksheet. Full factorial Design of Experiments (DOE) is a method used to study the effects of multiple factors on a response variable. In this type of experiment, all possible combinations of the levels of the factors are tested. This allows for the determination of the main effects and interactions of the factors on the ...

Experimental design techniques are designed to discover what factors or interactions have a significant impact on a response variable. Our SPC for Excel provides an easy-to-use design of experiments (DOE) methodology in the Excel environment you know. The SPC for Excel software contains the following DOE routines:

Design of Experiments, enables you to limit tests to the high (+) and low (-) values for any particular "design factor" (e.g., time, temperature, size, etc.), NOT every increment in between. AND you can test more than one factor at a time.

You can do this with Microsoft Excel, but dedicated math software is better suited for the task. There are multiple forms of DOE, each with an intended use. For purposes of learning, using, or teaching a design of experiments (DOE), one can argue that an eight-run array is the most practical and universally applicable array that can be chosen.